In the industry of metal finishing all of the process steps and control parameters are critical. Naturally most of all of the process steps are scrutinized, tracked, and analyzed, however often times those process steps that may not seem as critical should be not be taken lightly. One of these often over looked areas is rinsing and what constitutes good and efficient rinsing. The critical nature of rinsing can be measured in many ways such as component quality, process solution contamination or overall line process quality. The metrics may vary from application to application. Naturally … [Read more...]

Eliminating Cyanide from Your Copper Plating Process

There are a variety of copper plating technologies. These include acid copper, electroless copper, alkaline non-cyanide copper and alkaline cyanide copper. With the EPA’s Common Sense Initiative, plating facilities are moving away from the cyanide copper processes. The Common Sense Initiative impacts the automotive, iron and steel, computers and electronics, printing, petroleum refining and metal finishing industries. Its objective is to reduce or prevent pollution and the plan assigned a high priority to reducing or eliminating emissions of hexavalent chrome, chlorinated solvents, cadmium … [Read more...]

4 Quick Chromate Tips for the Winter

As we head into the fall and winter months, no doubt the service phone will start ringing about chromate rub off on zinc plated parts due to ambient going from temperatures in the 80s and 90s to temperatures in the 60s (and in some plants saving on heating bills, chromates may be trying to work as low as temperatures in the 50s). But as we see a rise in the trivalent chemistries and less of the "ambient" running hexavalent chromates, the simple fix of raising the temperature may not be the solution to the rub-off headache during these cold days of winter. Here are a few other quick tips to … [Read more...]

Hard Chrome Plating

The process of hard chrome plating has been used since the early part of the 20th century. It is a process that is used in nearly every aspect of manufacturing where wear resistance and lubricity are critical. Typically coating thickness deposited are between 8 to 250 mm (0.00032”-.0098”) and hardness between 800-1000HV. High hardness and resistance to abrasion are retained unchanged up to 200oC. Early processes were standard chromic acid and sulfate processes. The late 1940’s gave to processes that used anions such as fluoride to improve plating rates and finish quality. Evolutions in the … [Read more...]

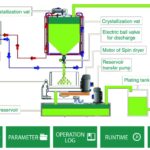

The Carbo-Dry Featured on Products Finishing Online

We’re proud to see the Carbo-dry system featured on Products Finishing Online among great companies and systems that make the product finishing industry more efficient and effective. You can read the full article here. Products Finishing Online has been the voice of the finishing industry since 1936. They provide information on the latest in research, white papers, technology and presentations from leading researchers in the finishing industry. … [Read more...]

Winning the War on Filth Part 1

Frustrated yet? I know I am. Over the last few years I have seen an increased number of parts showing up on my clients plating lines with more soils than ever before. This list includes stamping and machining oils as well as lubricants, rp's, and coolants. The part that frustrates me is that the soils I am seeing day after day are typically not new synthetics or reformulated petroleum based products. Instead, these are the same products that have been used for years, but now are used in quantities far greater than needed. Since it appears nobody can protect our process lines from the … [Read more...]

Zinc Plating

Years ago zinc plating was used for corrosion protection and was mainly applied using a cyanide based process. The process of plating zinc from an Acid Bath brought with it brighter deposit and Zinc Plating became a cosmetic finish as well as corrosion protective finish. In recent years the process of plating Zinc from an Alkaline Non Cyanide solution has been perfected. Today nearly all Zinc is plated from either the Acid Zinc or the Alkaline Non Cyanide processes. Each process has its positive and negative points. Acid Zinc produces a bright, level, Chrome like finish. The Alkaline … [Read more...]

Reducing Carbonates Every Day

Every Day, Asterion works to help our clients become more efficient, more productive and, most importantly, more profitable. As part of our efforts, we work with our clients to help them discover better methods to manage and control their plating baths. Over time we have learned quite a bit about the struggles our customers have in managing carbonates in alkaline plating baths. Accumulation of carbonates in alkaline plating baths is a continuous problem and can lead to a number of issues affecting quality and plating efficiency. The primary cause of formation of sodium carbonate is a … [Read more...]

Acid Wetter vs. Acid Inhibitor

In the process of electroplating of most ferrous substrates the pretreatment is extremely important since this is where it all begins. The pretreatment process is the foundation to the rest of the process being successful. Improper pretreatment may lead to poor plate coverage, poor adhesion, premature corrosion failures, and the list goes on. In the ferrous pretreatment process the typical process consists of an alkaline soak clean to remove surface soils such as cutting and lapping oils, stamping lubes, buffing compounds, heat treat oils, and rust preventatives. The soak clean provides for … [Read more...]